A2 tool steel is a 5 chromium medium alloy cold work tool steel possessing sufficient hardenability to be air hardened to 60 rc surface hardness level with good depth of hardening.

A2 tool steel hardness before hardening.

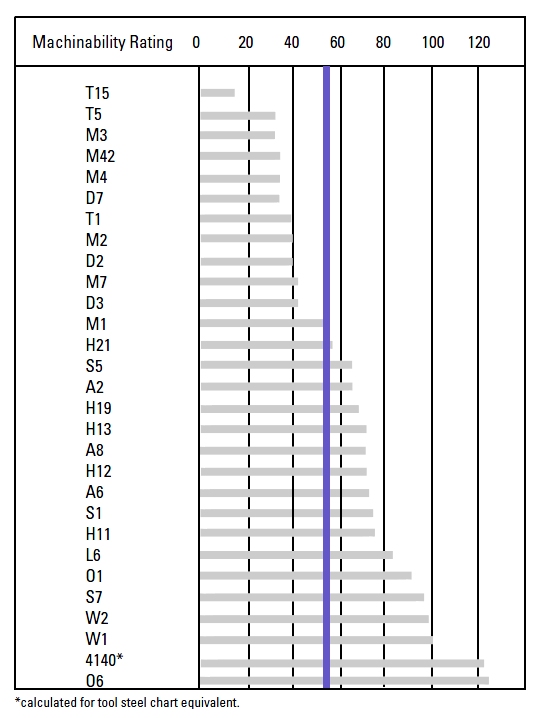

A2 is intermediate in wear resistance between o1 oil hardening tool steel and d2 high carbon high chromium tool steel.

A simplified guide to heat treating tool steels when we consider that the greater overall costs of most tools and dies are incurred prior to heat treatment and further that proper heat treatment is critical to the successful application of tooling this so called hardening process is placed.

It is heat treatable and will offer a hardness in the range 57 62 hrc.

Use for dies punches and similar forming and blanking tools as recommended for type o1 but where less distortion in heat treatment or better wear resistance is required.

The prefix a in the name designates it as an air hardening steel.

The data below will provide an overview of a2 air hardening medium alloy cold work tool steels.

A2 tool steel is an air hardening cold work steel.

Generally supplied annealed to hb 231 max.

The steel is composted of 1 percent carbon 3 percent silicon 6 percent manganese 5 3 percent chromium 1 1 percent molybdenum and 2 percent vanadium.

It is heat treatable and will offer a hardness in the range 57 62 hrc.

Aisi a2 is an air hardening tool steel containing 5 pct chromium.

The carbon content in a2 tool steels is high.

Aisi a2 tool steel is high carbon high alloy tool steel designed to have excellent wear resistance and toughness.

A2 steel is an air hardening cold work tool steel.

It s highly wear resistant and moderately tough.

It replaces o1 when safer hardening better dimensional stability and increased wear resistance are required.

A2 tool steel properties a2 is also an air hardening tool steel but includes less than half the chromium 4 75 5 50 and a bit less carbon 0 95 1 05 than d2.

A 5 chromium steel which provides high hardness after heat treatment with good dimensional stability.

A2 air hardening medium alloy cold work tool steels are a type of group a steels containing molybdenum and chromium.

A2 tool steel is a versatile air hardening tool steel that is characterized by good toughness and excellent dimensional stability in heat treatment.

A2 provides an effective combination of strength and toughness tool performance price and a wide variety of product forms.